How to Break the Bead on a Tyre (Tire)

Most tyres fitted these days are tubeless. To create an airtight seal, between the tire and the wheel, the tyre has to sit on the ‘bead’ around the rim of the wheel. To remove the tire, or get access to the wheel rim, the tyre has to be pushed off the bead. The term often used is ‘Breaking the Bead’.

Topics:

- Video

- How to Break the Tyre Bead:

- Use of Oil as a Lubricant:

- Summary:

- Other Similar Topics:

- Image Gallery:

Note:

Be careful with tyres… A tyre is a pressurised container. Any damage, or incorrect repair can cause a sudden loss of air which could be dangerous at speed (a blowout). Therefore please take care (any work you may carry out is at your own risk).

How to Break the Tyre Bead:

How to Break the Bead of a Tyre Bead – Two Easy Methods…

(Opens in a new tab)

There are two easy methods enabling you to break the bead of a tyre at home:

- First Method – Using a Trolley Jack:

- Second Method – Using Two Bits of Wood:

Methods Not Discussed Here:

- Driving another vehicle onto the tyre??

The First Method:

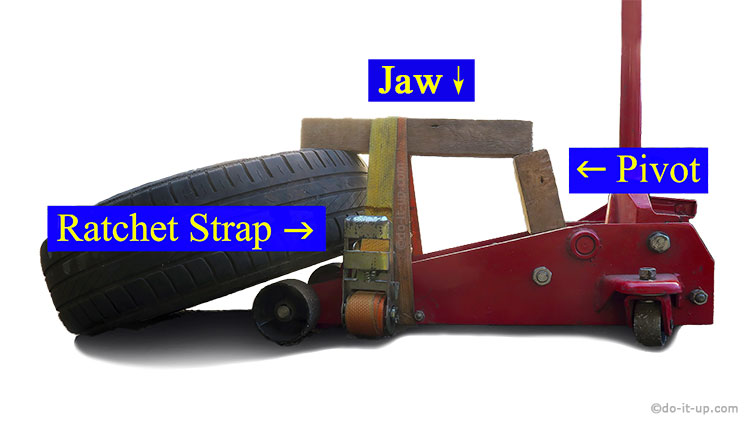

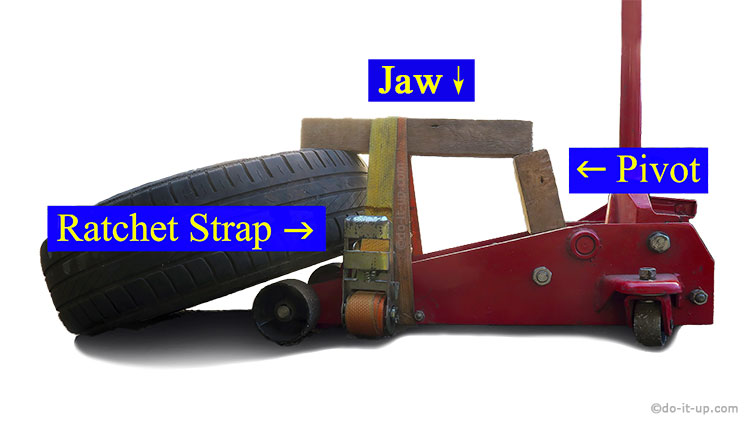

Using a Trolley Jack to Break a Tyre Bead:

Tools required:

- A Ratchet Strap.

- Two bits of wood (possibly three).

- A Trolley Jack.

Steps required:

- First, we need to let the air out of the tyre by pressing on the valve with a screwdriver, or something similar.

- Place the tyre on the jack.

- Use the two bits of wood to make a jaw for the jack to compress against. The other piece of wood is used as a pivot.

- Wrap the ratchet strap around the wooden jaw and the trolley jack.

- A third piece of wood can be used to support the tyre.

- Make sure the jack misses the wheel rim…

– For Safety –

Keep your fingers away from the tyre & rim when the jack is under pressure..!

- As you operate the jack, the tyre will compress against the wooden jaw and the tyre should pop off the rim.

Note:

I was unsuccessful with this method, but I can see how this would work. The main issue I had was that the ‘Pivot’ would slip. Other trolley jacks appear to have space where the pivot can be placed, that is fixed. Whereas I had to place the pivot on the jacking arm (that would tilt). Lots of other people have had success with this method, so give it a try…

Here are some additional thoughts:

- The pivot is maybe too high!

- This method may be more suitable for bigger tyres?

- The tyre was very tight on the rim.

- The shape of the jack and where you place the pivot (to prevent it from slipping), and the height of the pivot is the key to success…

The Second Method:

Using Two Bits of Wood to Break a Tyre Bead:

Tools required:

- Two bits of wood.

Steps required:

- First, we need to let the air out of the tyre by pressing on the valve with a screwdriver, or something similar.

- Try & find somewhere to lever against? This could be a bench with someone sat on it, another vehicle, etc, etc.

- Place the short piece of wood on the tyre to act as a pivot.

- The longer piece of wood is used as a lever to press down on the pivot, to release the tyre from the wheel rim.

- Just turn the wheel round to break more of the bead and repeat the process.

…I was surprised how easy this method was!

Use of Oil as a Lubricant:

Anything ‘generally oil based’ is not good at all for rubber and can cause the rubber to fail. One of the many quotes from Google…

“rubber in oil. It is a crosslinked polymeric material, and when all the bonds in the network are completely stretched due to a solvent that has diffused in, they cannot take any additional strain, and break very easily.”

Oil is also not good for synthetic rubber (made from crude oil). About 70% of rubber is currently synthetic. There are several lubricants that are safe to use with rubber (some synthetic oils??). But you would need to read the fine print, (and quite often they don’t tell you… ).

Solution:

One of the most common rubber lubricants is silicone grease, (which is often found in the plumbing section, because it is safe to use with rubber seals, o’rings, etc). I love the stuff, as it can be used on hoses; makes it easy to get them on and off (don’t use too much though!). Electrical contacts, plastics, etc. Without fear of damage. The only trouble is, it only comes in small pots or tubes, but can last a long time…

The good news is, a little lubricant would help a lot and does make the job easier. You’ve just got to be careful which lubricant you use…

Summary:

- The first method (using a trolley jack) was a bit fiddly and took more time to set up in comparison to the second method (two pieces of wood).

- The second method was much quicker and easier.

- The second method appeared to be a much safer process, as the tyre was only under pressure whilst I was pressing down on the lever. Whereas when using the trolley jack, the ratchet strap and tyre were under tension when the trolley jack was pumped up.

Other Similar Topics:

Image Gallery:

– click or tap the image to view full size –