How to Replace a Wheel Valve

I thought I had a slow puncture, but the air loss wasn’t coming from my tyre?

I had just pumped up my tire and disconnected the foot pump. When I noticed there was air escaping? I placed my finger over the end of the valve and could hear the change in noise (from the escaping air). On closer inspection, I found that the valve was leaking.

‘How to Replace a Wheel Valve’

Note:

This article applies to most wheels (or things) that are filled under pressure via a valve stem and a Schrader type valve… I.e. Cars, vans, trucks, motorcycles, wheelbarrows, bicycles, bikes, refrigeration, air conditioning systems, etc, etc.

Topics:

- Video:

- Testing:

- Tools Required:

- Replacing the Valve:

- Types of Wheel Valve:

- Other Similar Topics:

- Image Gallery:

For Safety:

Be careful with tyres… A tyre is a pressurised container. Any damage, or incorrect repair can cause a sudden loss of air which could be dangerous at speed (a blowout). Therefore please take care (any work you may carry out is at your own risk).

How do I Test & Replace the Valve Core?

It’s easy to change a wheel valve core (with the aid of a valve tool). Sometimes it can be a bit stiff to undo, but this is usually when the valve cap has gone missing…

Testing for Leaks on a Wheel Valve...

What to look for?

We can test the valve and valve stem with some soapy water (as long as there is some air in the tyre).

- Use a brush to apply the soapy water. Just apply a small amount on the valve (the threaded part). As you can see from the image, a small leak will give you some bubbles.

- If you see bubbles coming from any other part of the valve stem (not the threaded part at the top), or you can hear air is escaping when you move the valve stem with your finger. You could have a perished, or damaged valve stem. I have another article on replacing this… ‘How to Replace a Wheel Valve Stem‘ (link open in a new tab)…

Tools Required:

To remove a wheel valve, you need the following:

- Valve core removal tool.

- A small screwdriver (or similar to release the air).

Notes:

If you’re lucky, you can sometimes remove a valve core with long nose pliers, a small screwdriver, or make your own tool. However, the tool is inexpensive and you’re more likely to have success with the correct tool for the job…

Replacing a valve is straightforward and only requires an inexpensive wheel valve removal tool. There are a few different looking valve tools available. Usually, the only difference between them is the number of added features.

If you’re lucky, you may already have a wheel valve core removal tool. Sometimes you can find the tool included with air pumps and tyre pressure gauges. The image below shows a wheel valve removal tool on the end of a tyre pressure gauge.

The steel tools are usually a lot more robust than the plastic items. In the image below, the plastic tool is starting to get a bit chewed up…

How to Replace the Wheel Valve:

As long as you have the tyre valve tool, it’s an easy task to replace the valve.

What Are We Trying to do?

The inside of the valve stem has a thread which the valve screws into. To remove the valve core, you have to unscrew the valve. The center of the valve (the round bit in the middle) passes through a hole in the valve tool, allowing the tool to grip the two flat edges (see the image below), and undo the valve.

The image shows an 8mm Schrader type valve fitted to a bicycle inner tube.

Replacing the Wheel Valve:

Initial Check:

- Before removing, check if the valve is tight (and that it’s not just a loose valve).

- If it is loose… Tighten and re-test for leaks with soapy water.

Removing the valve:

– For Safety –

Let any remaining air out of the tyre. So the valve core doesn’t shoot out under pressure (when undone)…

- Press on the valve with a screwdriver, or something similar…

- Place the wheel valve removal tool on top of the valve. Insert the tool onto the flats of the valve (so the tool grips the valve) and unscrew.

- There may still be some trapped air that escapes whilst you unscrew the valve.

- Remove the valve, (if needed, long nose pliers may help in retrieving the valve from the hole).

- Insert a new valve and tighten.

If defective, do not try and repair the existing valve! Failure (a sudden loss of air) could be dangerous at speed (a blowout). Always replace with a new valve.

- Re-inflate the tyre to the recommended pressure and retest (if necessary).

- Always replace the valve cap. This keeps dirt and moisture out, and protects the valve.

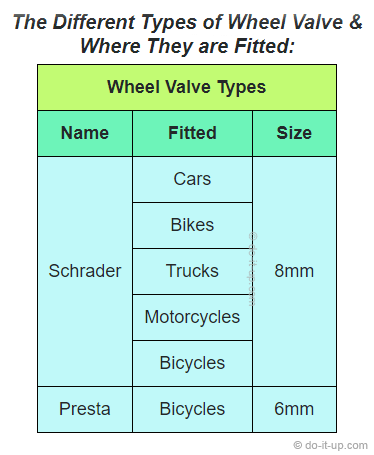

The Different Types of Wheel Valve:

There is usually only one type of valve fitted to an air filled wheel. A Schrader valve. Whereas with bicycles, there are two types, Schrader and Presta (Presta is smaller, for narrow bicycle wheel rims).

The Different Types of Wheel Valve & Where They are Fitted:

| Wheel Valve Types | ||

|---|---|---|

| Name | Fitted | Size |

| Schrader | Cars | 8mm |

| Bikes | ||

| Trucks | ||

| Motorcycles | ||

| Bicycles | ||

| Presta | Bicycles | 6mm |

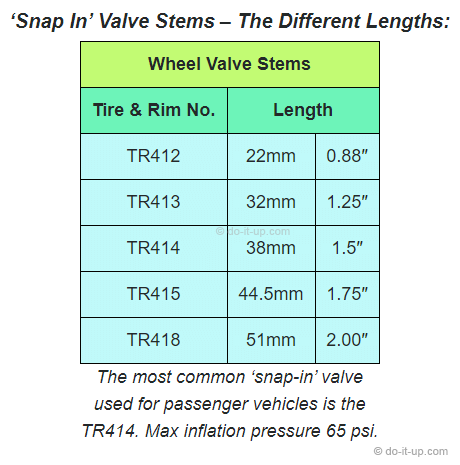

‘Snap-In’ Wheel Valve Stems:

The length of the valve stem is specified using the following references (see the table below):

‘Snap In’ Valve Stems – The Different Lengths:

| Wheel Valve Stems | ||

|---|---|---|

| Tire & Rim No. | Length | |

| TR412 | 22mm | 0.88″ |

| TR413 | 32mm | 1.25″ |

| TR414 | 38mm | 1.5″ |

| TR415 | 44.5mm | 1.75″ |

| TR418 | 51mm | 2.00″ |

Other Similar Topics:

Image Gallery:

– click or tap the image to view full size –