How to Fault Find & Troubleshoot Electric Motors

When an electric motor starts making a horrible noise, or it just stops, what do you do. Is it broken, is it repairable?

This article sets out to show you how to easily fault finding & diagnosis electric motors, (without a test meter). What to look for, when identifying an issue. Why it’s stopped, why it’s making a horrible noise, or why it’s not going very fast… It will help you decide if an item is repairable, or destined for the junkyard!

What are the Most Common Causes of Electric Motor Failure?

Easy Things you can Check:

We can break the motor diagnosis down into four distinct groups:

Topics:

- Does the Motor Smell?

- Does it Make a Horrible Noise?

- Have you Checked the Brushes..?

- If the Motor Doesn’t Smell & the Brushes are Fine, What do I do?

More info…

- Video:

- More Videos: (Opens in a new window / tab)

- Buying Parts for Electric Motors:

- Basic Fault Finding Thought Process:

- Related Articles:

* Electricity can Kill *

As with any electrical device…

Make sure the power is disconnected before examining by:

- Unplugging, physically disconnecting, or locking off the device.

- If you have a testing device, check the item is dead (the power is off) when opening any covers…

- Check and double check…

- If in doubt… Always consult a qualified electrician.

Video – Hints and Tips on Fault Finding an Electric Motor:

(Opens in a new tab)

Does the Motor Smell?

If the motor smells horrible, it’s usually a bad sign. It’s often because the motor has got too hot. The windings (wire) in an electric motor are covered in a varnish. The insulation is often made of plastic and can start to melt. Burnt varnish & plastic stinks. The smell is often dependant on how hot the electric motor has got, (and for how long). As a result, the insulation may have broken down and there maybe shorts in the electric wiring?

If something has completely burnt out, this can often mean it’s too expensive to repair. However, if it’s only a slight smell, it can still be worth checking, (Just in case the motor has only got a little warm)?

Things to Check?

Beware

An electric motor in a bad state, may be unsafe to use… The insulation may have partly broken down and may start to fail under load.

Firstly, is it safe to run the motor? Can it be rotated by hand (without disassembling the motor and with the power off!)?

If the motor rotates, does the device sound a bit rough? Sound is a good indicator of where a fault may lie…

- Is the motor starting to seize or is something rubbing?

- Visually check for any heat damaged areas. (follow your nose)?

- If you have a test meter, check the wiring. Is there anything obvious?

Notes:

- The residual smell will stay for quite some time, (for weeks)…

Warning

If you see smoke (or feel heat) it can be dangerous! The motor could be about to catch fire..!

- Stop the motor!

- Unplug from the mains.

- If you can, put somewhere outside (dry) to cool.

- Electric motors can get very, very hot when a fault occurs, especially when you start to see smoke!

Does the Motor Make a Horrible Noise?

Can you hear a noise? Noise can come from a number of places (in no particular order)…

Topics:

- Bearings (or bushes):

- Dust & Debris:

- Brushes:

- The commutator:

- Electrical noise:

- Frequency:

- Loose parts:

- Alignment:

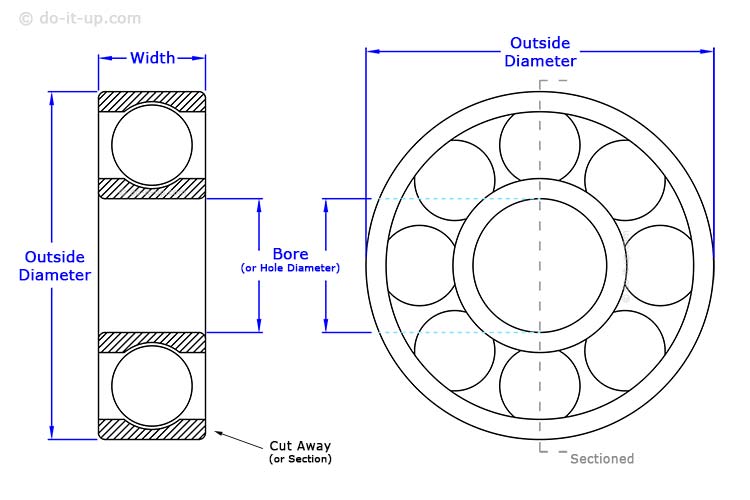

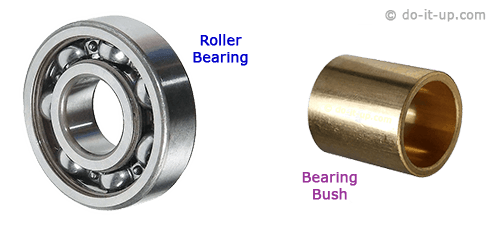

Bearings (or bushes):

Can make noise due to:

- Lack of oil or grease.

- Dirt ingress.

- Wear and tear, use and old age!

Bearings can be cleaned, or flushed out with a thin spray oil, then more oil or grease applied. They can be replace with new, (info on replacing bearings can be found in the following article – How to Measure & Buy a Replacement Bearing ).

Notes:

- Spray oils are often too thin and don’t last!

- Before applying oil or grease, try and determine whether oil or grease was the original lubrication used in the bearing when new.

The noise can also come from…

Dust & Debris:

Dust and debris can get in and clog up all sorts of places. It can block airflow for cooling, get into switches and speed controllers and cause the motor to rub and bind against the casing. In the case of ventilation fans, it can stop the fan blades rotating.

To remedy,

- Clean out and make sure the motor can breathe (cooling).

- Remove obstructions that could slow or stop the motor from turning.

Brushes:

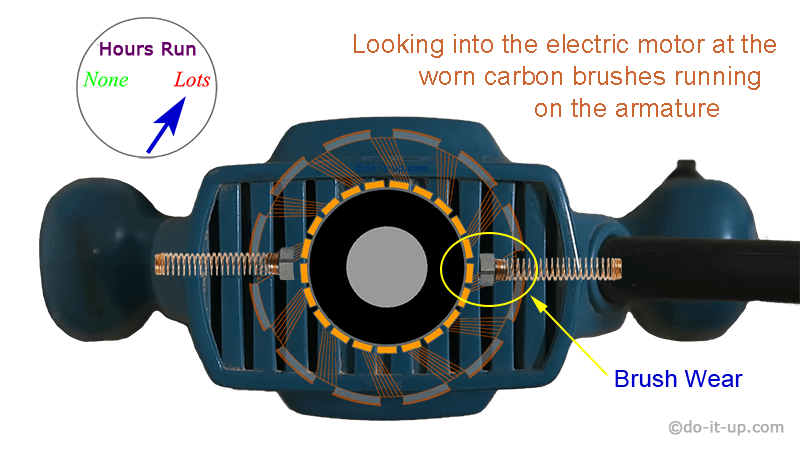

Check to see if the brushes are worn? Worn brushes can cause additional sparking, erratic running of the motor, juddering, etc. This can also make additional noise.

The commutator:

Check if the commutator is worn or dirty (usually carbon dust from the brushes, or from sparking). The lack of electrical contact, or a rough, bumpy running surface can cause:

- Erratic running.

- Slow speed.

- And additional noise.

Electrical noise:

Can be caused by any of the reasons above, but it may also be due to impending doom! If there are any faults, or the insulation is starting to break down, the motor may start misbehaving, drawing more current, making more noise.

Frequency:

Sometimes the rotating speed can create vibrations (especially fan blades).

Things to look out for:

- Lots of sparking and additional noise.

- Loss of power.

Loose parts:

Has something come undone. Is it rattling around inside the casing?

Alignment:

Something bent, or not assembled correctly? It’s not unknown for a motor casing not to be correctly re-assembled (after being taken apart for investigation). Especially with power tools and their plastic casings that can flex prior to assembly. A slight misalignment when screwing back together can mean something starts to rub, misalignment of the brushes, etc.

Notes:

- If it starts humming, that’s bad news. Switch off immediately.

- The motor may have jammed.

- This can lead to smoke and fire!

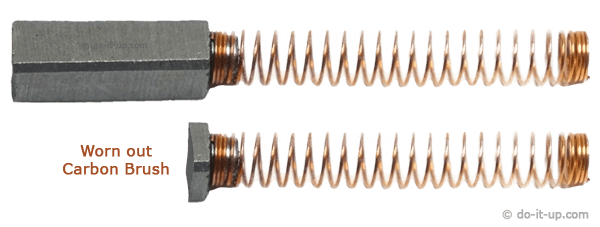

Have the Carbon Brushes Worn Out?

Carbon brushes fitted to an electric motor are designed to wear out, (more expensive motors may not have brushes fitted). Brushes are very cheap, in comparison to the cost of an armature. If the brushes were made of a harder material, the commutator would wear out first. This would result in a much more expensive repair and quite possibly, a terminal fault.

Therefore, it’s always worth checking the brushes (if fitted).

Topics:

- Carbon Brushes:

- A Quick ‘Weird’ Temporary Fix..?

- Don’t Leave it Too Late!

- Brush Damage / Armature Damage?

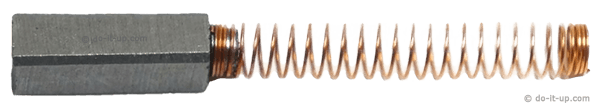

Carbon Brushes:

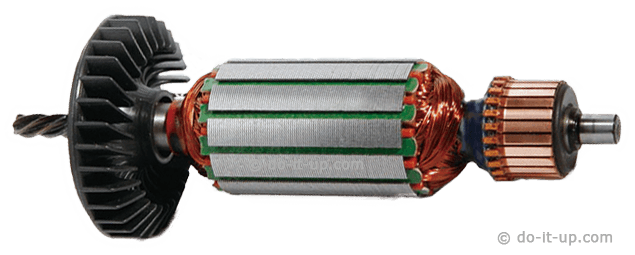

The main task of carbon brushes, is to pass electricity to the motor armature.

Please note that you can get more expensive (and often more reliable) brushless electric motors.

Therefore, carbon brushes aren’t always fitted.

- Small springs are used to push the carbon brushes against the motor armature to make electrical contact.

- Carbon is cheap. Carbon brushes are designed to wear away, (rather than the expensive armature).

- It’s not often that anyone explains that… Carbon brushes are a consumable item (dependant on hours run).

Carbon brushes are often housed in brush holders. These allow the brushes to slide in and out (with the aid of a spring). As the brushes wear, they are pushed towards the armature by the spring. This ensures there is continuous electrical contact.

Notes:

- You can get lots of different shapes & sizes of carbon brush holders.

- Sometimes the brush holders are:

- Removable, (by dismantling the motor housing).

- Are fixed, but the brushes are removed, (by dismantling the motor housing).

- Or, there is an external cover that’s removed to gain easy access.

A Quick ‘Weird’ Temporary Fix..?

- Before taking the motor apart. Try tapping the motor with a piece of wood, (or something similar)…

- This can dislodge the brushes, (the spring has less force as the bushes wear and they can get stuck). This may allow electrical contact to be made for just a little bit longer…

- This doesn’t always work, but was an old trick used on vehicle starter motors (when they wouldn’t run) and was used to just to get you home.

Just remember that…

If it works, it’s only a temporary fix. Replace the brushes as soon as possible, or more damage may occur…

Don’t Leave it Too Late!

Important! If the carbon brushes are worn, they can…

- Cause excessive sparking on the armature.

- The motor may…

- just stop.

- Start making additional noise,

- The motor may run erratically.

- The power output may be reduced.

If the electric motor is allowed to run in this state, it could start running on the brush springs, damaging the armature?

Brush Damage / Armature Damage?

A double edged sword… Sometimes the brushes can damage the armature, sometimes the armature can damage the brushes!

The Brushes:

If the brushes wear away completely, the motor can end up running on the springs. The brush springs are a lot harder than carbon and and can wear the commutator. In most cases the springs can short out and blow the commutators, causing complete failure. Therefore, don’t run the motor on the springs, (you can usually tell by the noise and excessive arcing).

The Sequence…

- The brush(es) wear away.

- The motor runs on the spring(s).

- Increased noise.

- The commutators to blow!

The Armature:

Check to see if the armature commutator is worn or dirty:

- The armature can wear the brushes at a faster rate.

- Additional arcing can cause increased brush wear.

Cleaning the Armature (Commutator):

If the brushes appear to be OK, check and clean the commutator as follows:

- Clean with a soft cloth or tissue. – If needed, use an eraser to see if any more dirt can be removed.

- If there are score marks, or the commutator is still dirty. Use a very fine abrasive or scourer. If there are any marks that will increase the brush wear, then an attempt should be made to smooth these out. You should be trying to remove as little of the commutator surface as possible.

- The gaps between each of the commutator segments, should be checked to ensure they are free from any conductive material. Otherwise a short could occur. Be gentle to prevent any damage.

- Check the brushes have a good electrical connection to the wiring, as the electrical connections could fail. I.e. the brush to the brush housing, the brush housing to the wiring, etc. The brushes should not need bedding in. The rotation and use of the motor should do it for you.

Any low power or sparking could be due to the motor coil(s) breaking down under load. Check their resistance if you can. They may seem fine on testing, but could then break down under load, making it difficult to spot.

Notes:

- If the armatures blown, there’s not a lot you can do, other than fit a new armature.

- It’s important to replace the brushes before they completely wear out (and is a cheap solution).

- Sometimes the brushes just happen to be nearly worn out, and the fault can be somewhere else! Therefore, it’s worth checking for other faults?

If the Motor Doesn’t Smell & the Brushes are Fine, What can I do?

(or, it’s a Brushless Electric Motor?)

Topics:

- Check the Wiring:

- Starting Capacitors – Will the Motor Run if you Help it Spin?

- Thermal Protection:

- Switches, Speed Control & Gizmo’s:

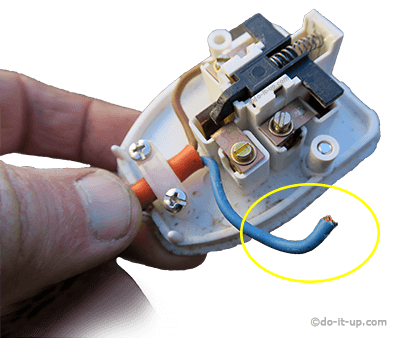

Checking the Wiring:

- Look for open circuits, (broken wires, loose cables) in the motor circuits.

- If a plug is fitted, check the fuse.

- Check for external broken cables (e.g.extension leads).

- Test the continuity.

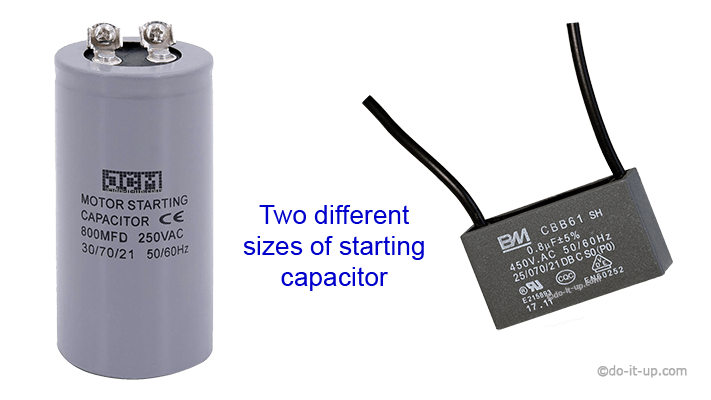

Starting Capacitors – Will the Motor Run if you Help it Spin?

If yes, then it could be a defective starting capacitor. The capacitor gives the motor an additional boost to get it spinning. Once running, the motors own momentum will keep it going.

It can be a simple fix to replace the starting capacitor.

Thermal Protection:

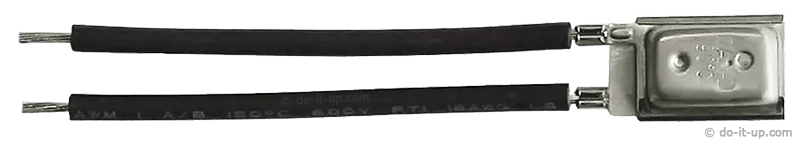

Please note that not all electric motors are fitted with Thermal protection...

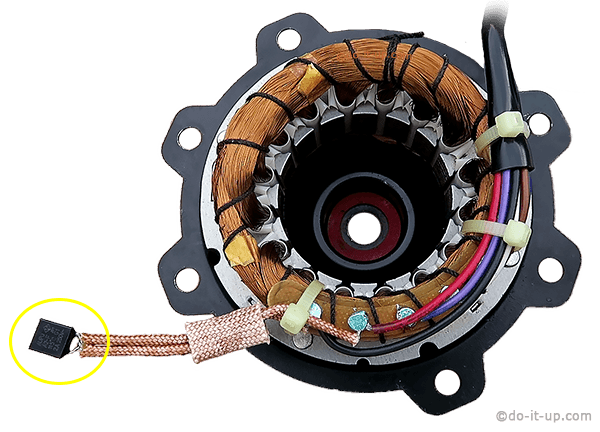

Electric motors can be fitted with thermal trip to protect the motor from overheating. They will often be placed near to the motor windings, where heat is generated.

The are often two types of thermal Protection:

Resettable:

Resettable thermal trips break the supply to the electric motor. The resetting process often requires you to wait for the motor to cool.

Notes:

- It’s often advisable to check the motor over to try and find out why the motor overheated?

- Make sure it’s not a ‘thermal fuse’ as a thermal fuse will need replacing…

Non-resettable (a fuse):

Non-resettable thermal fuses are often quite small, so it may not be immediately obvious that the motor has one fitted.

Notes:

- They often have an ‘amp’ rating like most fuses.

- If the thermal fuse has blown, the motor won’t run.

- A new thermal fuse will be needed.

- Make sure it’s not a ‘thermal trip’ as a reset may be required…

Switches, Speed Control & Gizmo’s:

I’m using the term ‘Gizmo’s’ for any additional items, bells and whistles that may be fitted to an electric motor…

Switches, speed control and gizmo’s can go defective. There can be a number of reasons why, and the list is not exhaustive.

- Broken wires.

- Burnt out.

- Component failure.

- Dust.

- Old age, wear and tear…

With ‘Gizmo’s’, all you can do is check for the usual electrical faults. Note that, electric motors generate heat and often have a fan to draw in air for cooling. These fans pull in dust and debris which can cause issues?

- Like water, dust can get into all sorts of places you don’t expect.

- If the motor is ‘in something’, it’s always worth checking there is adequate air flow for cooling.

- In the case of powered hand tools, beware of blocking airways with your hands.

Buying Parts for Electric Motors:

If you’re not sure what you need, sometimes it’s a good idea to have a look? The list below may give you an idea of what’s available, what to look for, and how much the part might cost…

Carbon Brushes, Bearings and Electric Motor Parts:

| Motor Parts | |

|---|---|

| Item | Location |

| Carbon Brushes |  UK Prices

UK Prices

|

US Prices

US Prices

|

|

AU Prices

AU Prices

|

|

| Bearings |  UK Prices

UK Prices

|

US Prices

US Prices

|

|

AU Prices

AU Prices

|

|

| Bushes |  UK Prices

UK Prices

|

US Prices

US Prices

|

|

AU Prices

AU Prices

|

|

| Armature |  UK Prices

UK Prices

|

US Prices

US Prices

|

|

AU Prices

AU Prices

|

|

| Test Meter |  UK Prices

UK Prices

|

US Prices

US Prices

|

|

AU Prices

AU Prices

|

|

Thank you for your support.

Basic Fault Finding Thought Process:

Some basic thoughts on narrowing down where a fault may be occurring…

- Broken wire – No power at all, or intermittent power.

- Brushes – Motor runs slow, lots of sparking, or no power. May have power for a while after taping the sander to reseat the brushes.

- Commutator – Lots of sparking, or sudden failure.

- Intermittent power – Loose connection, (or a broken wire making and breaking).

- Starting capacitor – The motor runs slow, or not at all.

- Windings – No power (sudden failure), or it starts to get very hot before failing.

Note:

The above are general descriptions, as you can get all sorts of weird electrical faults!

Related Articles:

How to Measure & Buy a Replacement Bearing: