TIG Filler Rods (Filler Wire)

Topics:

- The Different Types of TIG Filler Rods (An Overview):

- TIG Wire Rod (Filler Wire) Sizes:

- Image Gallery:

The Different Types of TIG Filler Rods (An Overview):

As with all the other TIG consumables, TIG filler rods come in a variety of materials, sizes and specifications.

Here are the common material groups:

- Steel (& Low Alloy).

- Stainless Steel.

- Aluminium.

- Chrome Moly (Chromoly).

- Cast Iron.

- Copper & Copper Alloys (Brazing).

- Nickel Alloys.

Each of the TIG wire material groups listed above can have a variety of different alloy ‘sub groups’ listed, tailored to specific uses. Don’t get bogged down by all the different types. You can spend hours examining the different properties of each one (unless of course, you’re welding something very specific).

Having said that though, their are some key differences which I will try and set out below:

For instance, mild steel may come with a reference A15 or A18…

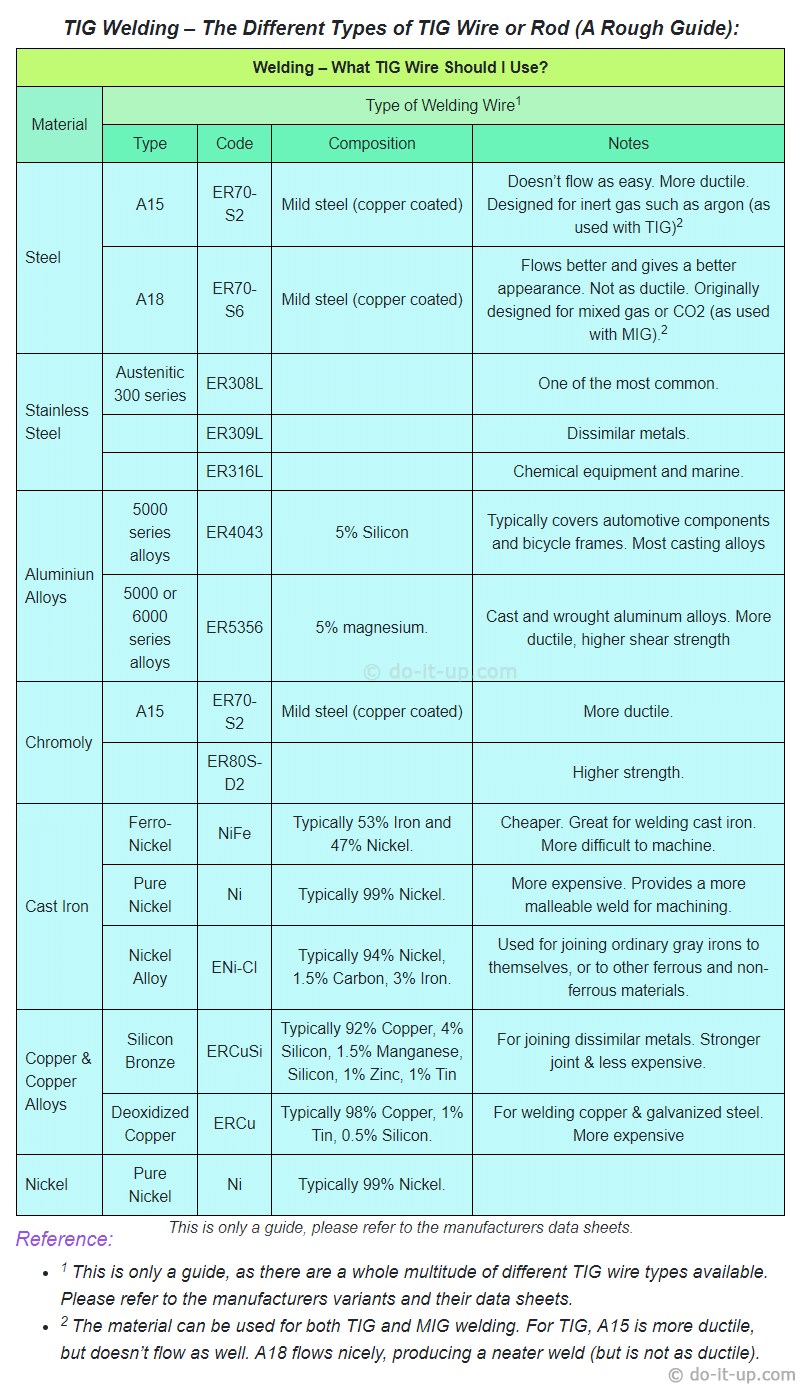

TIG Welding – The Different Types of TIG Wire or Rod (A Rough Guide):

| Welding – What TIG Wire Should I Use? | ||||

|---|---|---|---|---|

| Material | Type of Welding Wire1 | |||

| Type | Code | Composition | Notes | |

| Steel | A15 | ER70-S2 | Mild steel (copper coated) | Doesn’t flow as easy. More ductile. Designed for inert gas such as argon (as used with TIG)2 |

| A18 | ER70-S6 | Mild steel (copper coated) | Flows better and gives a better appearance. Not as ductile. Originally designed for mixed gas or CO2 (as used with MIG).2 | |

| Stainless Steel | Austenitic 300 series | ER308L | One of the most common. | |

| ER309L | Dissimilar metals. | |||

| ER316L | Chemical equipment and marine. | |||

| Aluminiun Alloys | 5000 series alloys | ER4043 | 5% Silicon | Typically covers automotive components and bicycle frames. Most casting alloys |

| 5000 or 6000 series alloys | ER5356 | 5% magnesium. | Cast and wrought aluminum alloys. More ductile, higher shear strength | |

| Chromoly | A15 | ER70-S2 | Mild steel (copper coated) | More ductile. |

| ER80S-D2 | Higher strength. | |||

| Cast Iron | Ferro-Nickel | NiFe | Typically 53% Iron and 47% Nickel. | Cheaper. Great for welding cast iron. More difficult to machine. |

| Pure Nickel | Ni | Typically 99% Nickel. | More expensive. Provides a more malleable weld for machining. | |

| Nickel Alloy | ENi-CI | Typically 94% Nickel, 1.5% Carbon, 3% Iron. | Used for joining ordinary gray irons to themselves, or to other ferrous and non-ferrous materials. | |

| Copper & Copper Alloys | Silicon Bronze | ERCuSi | Typically 92% Copper, 4% Silicon, 1.5% Manganese, Silicon, 1% Zinc, 1% Tin | For joining dissimilar metals. Stronger joint & less expensive. |

| Deoxidized Copper | ERCu | Typically 98% Copper, 1% Tin, 0.5% Silicon. | For welding copper & galvanized steel. More expensive | |

| Nickel | Pure Nickel | Ni | Typically 99% Nickel. | |

Reference:

- 1 This is only a guide, as there are a whole multitude of different TIG wire types available. Please refer to the manufacturers variants and their data sheets.

- 2 The material can be used for both TIG and MIG welding. For TIG, A15 is more ductile, but doesn’t flow as well. A18 flows nicely, producing a neater weld (but is not as ductile).

Notes:

- Tig and gas welding rods (wire) are not always the same. Check the manufacturer’s data sheets.

- For sheet metal, a mild steel filler rod should never be bigger than the thickness of the material – Under 3.2mm (1/8″). For stainless steel, use one size lower (Stainless steel uses less amperage. A large rod cools the weld too quickly). Aluminium wire rods tend to start at 1.6mm.

- Don’t have the right size filler wire? As a stop gap, mig wire wound together using a drill can make a larger size filler wire.

- Practice welding can be done with filler wire made from scrap strips of the base material.

TIG Wire Rod (Filler Wire) Sizes:

If you’re unfamiliar with purchasing filler wire, it’s good to visualise what you’re going to get. The table below gives a rough guide on how many TIG rods you may get in a pack (by weight):

TIG Welding – Number of Filler Rods (or wire) by Weight:

| TIG Welding – Number of Rods by Weight | ||||

|---|---|---|---|---|

| Material | Size | Contents1 | ||

| mm | Inch | 1KG | 5KG | |

| Steel & Stainless Steel | 1.00 | 3/64 | 165 | 825 |

| 1.60 | 1/16 | 65 | 325 | |

| 2.40 | 3/32 | 28 | 140 | |

| 3.20 | 1/8 | 18 | 90 | |

| 4.00 | 5/32 | |||

| 4.80 | 3/16 | |||

| 1KG | 2.5KG | |||

| Aluminium2 | 1.60 | 1/16 | 190 | 475 |

| 2.40 | 3/32 | 84 | 200 | |

| 3.20 | 1/8 | 46 | 115 | |

| 4.00 | 5/32 | |||

| 4.80 | 3/16 | |||

Reference:

- 1 All figures are approximate.

- 2 Aluminium filler rod sizes generally start at a size of 1.6mm (1/16″).

Image Gallery:

– click or tap any image to view full size –