How to Repair or Replace a Head Gasket

Intro…

The images below show what’s involved in repairing a cylinder head gasket, from the initial strip down to re-assembly. Modern engines are fairly complicated, with numerous additions to help the engines efficiency, smoothness and control. However, the task is fairly straight forward, it just takes time, energy and some mechanical engineering ability. If you’re not planning to do the job yourself, the images may give you an idea of what is involved and why garage costs can be high.

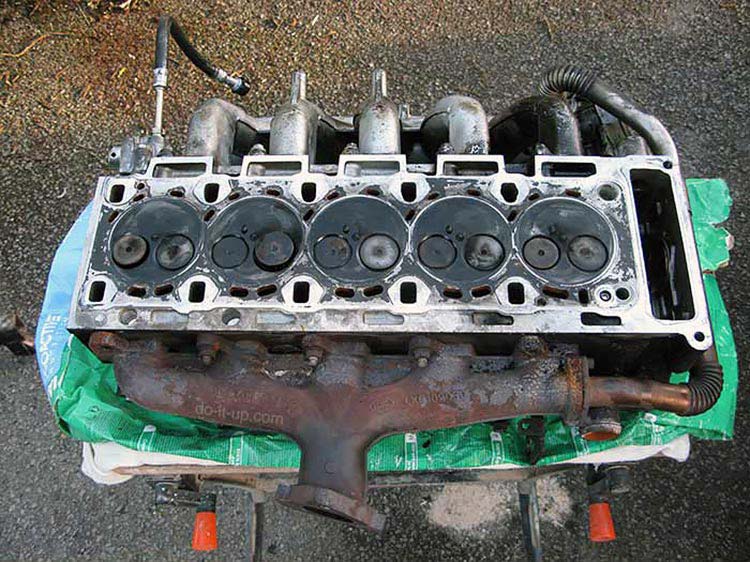

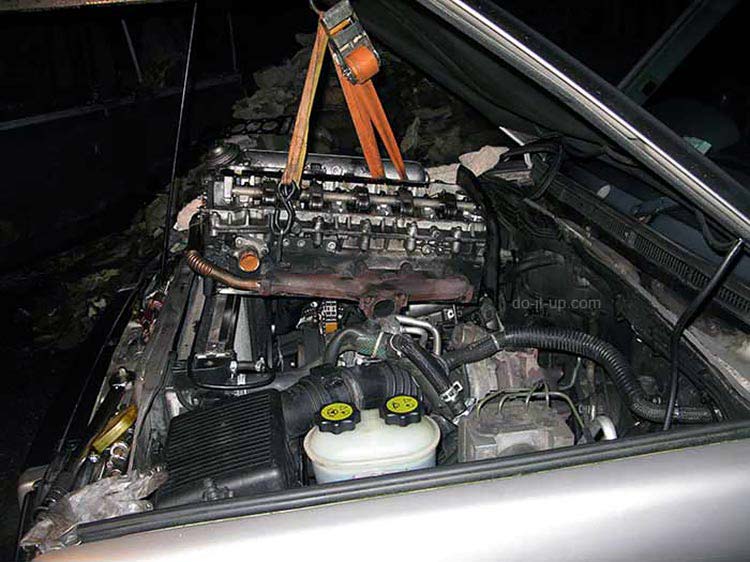

The vehicle in this example is a 2.5 litre, 5 cylinder Land Rover TD5 diesel engine, so it’s of a reasonable size and weight. An engine hoist is used to lift the cylinder head off, as the head still has lots of ancillary components attached, (I have seen others lift this size head off by hand). Smaller engines should be no problem weight wise.

Topics:

Head Gasket – Description:

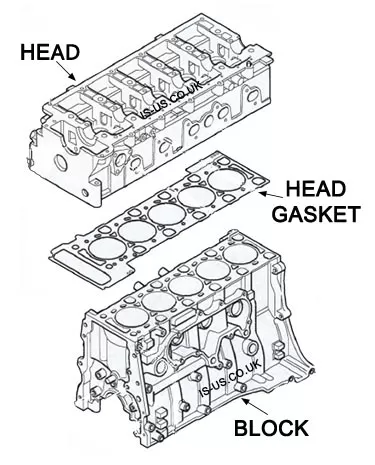

The biggest single components of the engine (excluding the gearbox) are the ‘block’ and the ‘cylinder head’. Most components are contained within, or attached to them.

The cylinder head is placed on top of the block. The two are held together with cylinder head bolts and the joint between the two parts is sealed with a cylinder head gasket.

The head gasket is important because it keeps the engine coolant, oil and combustion gasses from escaping, or mixing with each other.

Main Tasks Required to Replace the cylinder head Gasket:

Mouse over or touch the screen to pause the slide show, drag the images or use the direction arrows.

The following is a rough list of the steps required to remove the engine cylinder head.

- Disconnect the battery, drain the water.

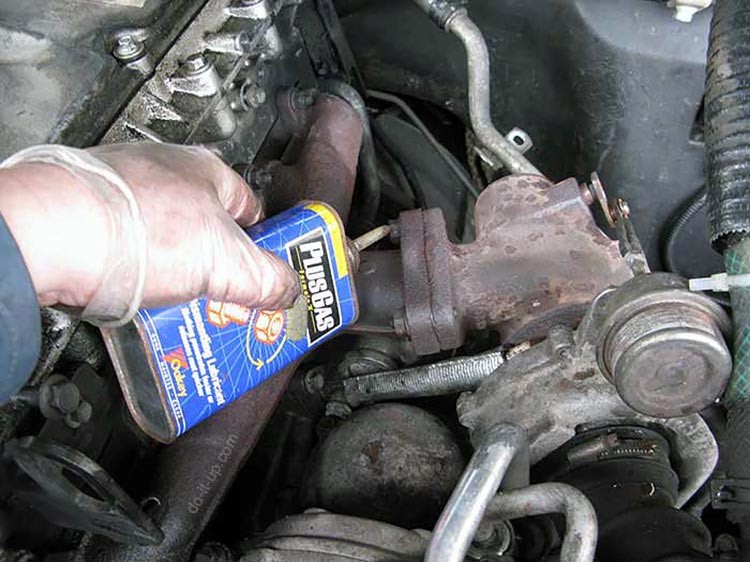

- Remove ancillary equipment (covers, brackets, pipes, hoses, cables, cooling fan, turbo, fuel lines etc) and any other items that may be in the way. This can be the task that takes the most time.

- Remove any associated fixing bolts, camshaft cover and cylinder head bolts.

- Lift off the cylinder head.

- Check the cylinder head and block for damage, clean.

- Have the cylinder head skimmed and overhauled (if necessary).

- Fit a new cylinder head gasket.

- Replace the cylinder head (reversal of dismantling).

Fault Finding:

The Symptons:

(These are based on my own experiences):

Symptoms of a ‘blown’ head gasket may be a combination of the following:

- Overheating, (if the engine is electronically controlled, the vehicle may go into limp mode).

- Loss of coolant (no visible leaks).

- Loss of coolant (by over pressurisation).

- Expansion tank still pressurised when the engine is cold.

- Bubbles in the expansion tank when the engine is running.

- Steam coming from the exhaust (coolant).

- Smoke coming from the exhaust (Oil).

- There is oil in the cooling system.

- There is water in the oil (a whitish creamy colored sludge, usually inside the oil filler cap, or on the dipstick).

- Lack of compression on one, or several of the engine’s cylinders.

- The vehicle misfires or runs roughly (due to a combination of the above).

The Fault on this Particular Vehicle Was:

- Pressurised radiator/expansion tank (when the cooling system is cold).

- The engine overheated (and the engine management system went into limp mode).

- Coolant was expelled from the cooling system.

- The coolant level fell with no apparent leaks in the cooling system.

Symptom Description:

Pressure:

Under normal conditions, when the engine is hot, the coolant system is under pressure (due to heat expansion). When the system is cold, there should be little or no pressure.

If the coolant system is pressurised when cold, there must be something in addition to the heating and cooling process pressurising the system. The main source of additional pressure can be from a faulty head gasket, where the engine operation has over pressurised the coolant system.

Water Contamination or loss:

Water can escape through a faulty head gasket and exit the vehicle through the exhaust, or enter the oil lubricating system. It can also be expelled from the cooling system by over pressurisation as described above.

Oil Contamination or Loss:

Oil enters the coolant system through a faulty head gasket, or is burnt, expelled through the exhaust.

Lack of Compression:

The upward movement of the engine’s pistons, compress the air and fuel mixture in each of the engine’s cylinders. If there is a faulty head gasket, the compression is reduced in one or more engine cylinders, as the head gasket seal may be broken and pressure generated by the piston can escape.

Testing:

There are several tests that can be performed. They may not always directly point to a fault but can provide an indication. Sometimes you have to go on gut instinct and putting 2+2 together because of a combination of fault indicators.

- Check for steam in the exhaust, or smell of coolant.

- Look for smoke in the exhaust (loss of oil).

- Look for oil in the coolant (loss of oil).

- Look for bubbles in the expansion tank (when the engine is running).

- Pressure testing the cooling system.

- To look for visible leaks in the coolant system.

- To see if pressure is maintained (no visible leaks).

- To see if pressure increases when the engine is run – Above the normal operating pressure (over pressurisation).

- Pressure, or compression testing the engine.

- Testing for hydrocarbons (exhaust gases) in the cooling system. You can buy a kit, or a garage can test it for you.

Precautions:

Safety is important – Follow the precautions contained in the vehicle handbook/repair manual. They are there for your safety.

Repair:

The repair involves:

- Draining the coolant.

- Removing all the items that connect the head to other parts of the vehicle.

- Unbolting the head and lifting it off the block.

- Removing the old gasket.

- Inspecting for damage.

- Cleaning and inserting a new gasket.

- Re-assembly.

Additional Issues:

Additional issues can be discovered, once the head is removed.

- A warped head (caused by overheating).

- Damage caused by corrosion / erosion.

- Cracked cylinder head or block.

Note: Items 2 & 3 are the worst case scenarios and are less common (see below:).

Detail:

- A warped Head – If the head has warped, but is still within machining tolerances; the repair will involve removing all the components from the head and getting a machine shop to ‘skim’ the head. This is common practice if a head is warped.

- Corrosion / Erosion – if not too excessive, it is possible to do a repair using a number of methods (specialist filler, weld, or insert), but it may not be a ‘guaranteed’ fix.

- Cracked cylinder head or block – Normally a replacement has to be sought. If your lucky, a specialist can perform a ‘stitch’ repair.

Head Gasket Cost

The charges for replacing the head gasket can be high due to a large amount of labour, typically 75% (with newer vehicles, a large number of items have to be disconnected to remove the head).

If you have the confidence, performing the task yourself can save the large labour costs.