TIG Tungsten Electrodes:

Tungsten electrodes come in a variety of types and sizes. Which Tungsten electrode you use, may be dependant on what you want to weld?

Here is a list of the most common Tungsten electrodes:

- Ceriated 2% (Gray) – Sometimes Orange:

- Thoriated 1% (Yellow):

- Thoriated 2% (Red):

- Lanthanated 1% (Black):

- Lanthanated 1.5% (Gold):

- Lanthanated 2% (Blue):

- Pure (Green):

- Rare Earth (Purple):

- Zirconiated 0.8% (White) – Sometimes Brown:

Note:

- Many suppliers only stock their most popular selling items.

How are Tungsten Electrodes Made – Why all the Differences?

Tungsten electrodes are made by adding small quantities of metallic oxides (Cerium, Thorium, Lanthanum, etc) using a process called Sintering… “Compacting and forming a solid mass by heat or pressure, without liquefaction”.

The reason these oxides are added, is to enhance the performance of the electrodes. I.e. Their current carrying capacity, longevity, arc stability, etc. Each oxide can give slightly different characteristics when welding. Therefore, some oxides are more suited to a particular material (see the table below: “The Differences Between Tungsten Electrodes”).

Topics:

- The Differences Between TIG Tungsten Electrodes:

- Tungsten Electrode Sizes:

- Adjusting a Tungsten Electrode:

- Image Gallery:

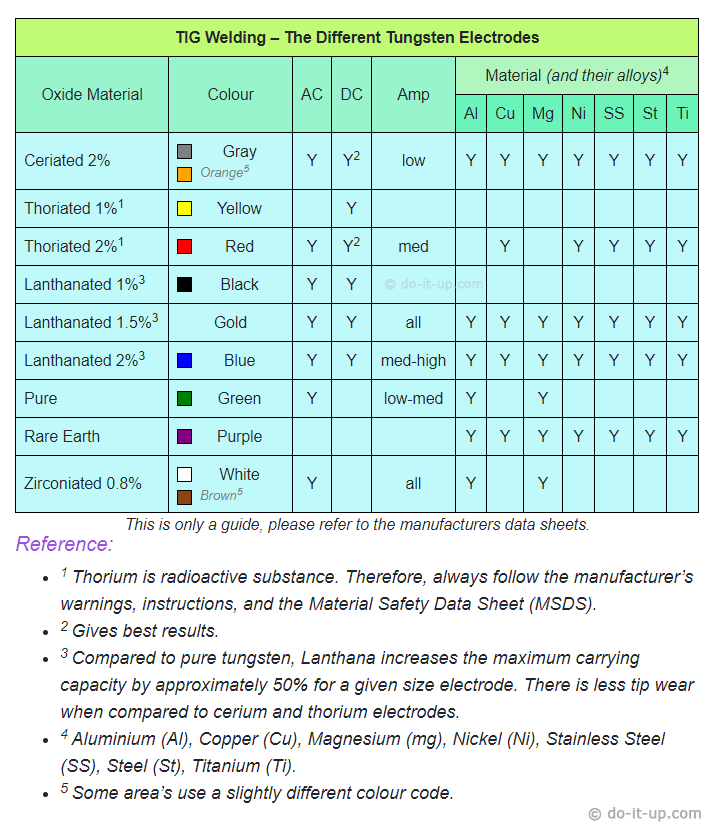

The Differences Between TIG Tungsten Electrodes:

The table below tries to set out the differences between tungsten electrodes. However, there are many slight differences between each electrode, (and all the detail can’t fit in one table). So try to check any data sheets (if available).

TIG Welding – The Differences Between Tungsten Electrodes:

| TIG Welding – Tungsten Electrodes | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Material | Colour | AC | DC | Amp | Material (and their alloys) 4 | ||||||

| Al | Cu | Mg | Ni | SS | St | Ti | |||||

| Ceriated 2% | Gray Orange 5 | Y | Y 2 | low | Y | Y | Y | Y | Y | Y | Y |

| Thoriated 1% 1 | Yellow | Y | |||||||||

| Thoriated 2% 1 | Red | Y | Y 2 | med | Y | Y | Y | Y | Y | ||

| Lanthanated 1% 3 | Black | Y | Y | ||||||||

| Lanthanated 1.5% 3 | Gold | Y | Y | all | Y | Y | Y | Y | Y | Y | Y |

| Lanthanated 2% 3 | Blue | Y | Y | med-high | Y | Y | Y | Y | Y | Y | Y |

| Pure | Green | Y | low-med | Y | Y | ||||||

| Rare Earth | Purple | Y | Y | Y | Y | Y | Y | Y | |||

| Zirconiated 0.8% | White Brown 5 | Y | all | Y | Y | ||||||

Reference:

- 1 Thorium is radioactive substance. Therefore, always follow the manufacturer’s warnings, instructions, and the Material Safety Data Sheet (MSDS).

- 2 Gives best results.

- 3 Compared to pure tungsten, Lanthana increases the maximum carrying capacity by approximately 50% for a given size electrode. There is less tip wear when compared to cerium and thorium electrodes.

- 4 Aluminium (Al), Copper (Cu), Magnesium (mg), Nickel (Ni), Stainless Steel (SS), Steel (St), Titanium (Ti).

- 5 Some area’s use a slightly different colour code.

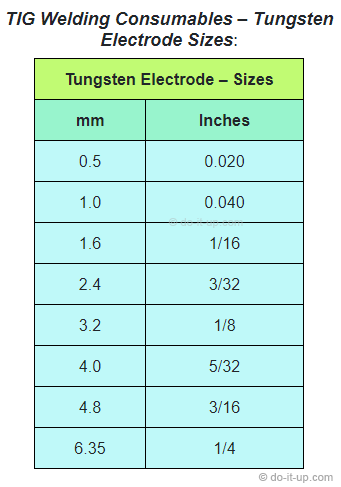

TIG Tungsten Electrode Sizes:

TIG Welding Consumables – Tungsten Electrode Sizes:

| Tungsten Electrode – Sizes | |

|---|---|

| mm | Inches |

| 0.5 | 0.020 |

| 1.0 | 0.040 |

| 1.6 | 1/16 |

| 2.4 | 3/32 |

| 3.2 | 1/8 |

| 4.0 | 5/32 |

| 4.8 | 3/16 |

| 6.35 | 1/4 |

Summary:

The general opinion online appears to be that Lanthanated 1.5% (Gold) electrodes appear to be taking over from Thoriated 2% (Red)1 as one of the most popular ‘multi purpose’ types of Tungsten electrode. For best results on Aluminium or Magnesium, use a Zirconiated 0.8% electrode.

As always, a specific job may be suited to a particular electrode. Therefore please read the manufacturers data sheets to check suitability.

Notes:

- A Tungsten electrode must be ground longitudinally (lengthwise). If ground in another direction, the surface finish can effect the current flow and the performance of the arc.

- Cut the end of a contaminated electrode off before re-grinding. Just grinding a contaminated electrode may contaminate the grinding surface.

- 1 Do not breathe the dust from Thorium electrodes, as Thorium is a radioactive substance.

- Always follow the manufacturer’s warnings, instructions, and the Material Safety Data Sheet (MSDS).

Adjusting a Tungsten Electrode (When fitted):

Loosen the TIG torch back cap and move the Tungsten electrode to the position required. Retighten the back cap.

Notes:

- Make sure the TIG torch has cooled before adjusting.

- Sometimes the Tungsten electrode can stick, so a little ‘jiggling’ may be needed.

- Wedge collets work in a slightly different manner – An offset chamfer forces the collet to one side when screwing in the back cap.

Image Gallery:

– click or tap the image to view full size –