TIG Gas Cup:

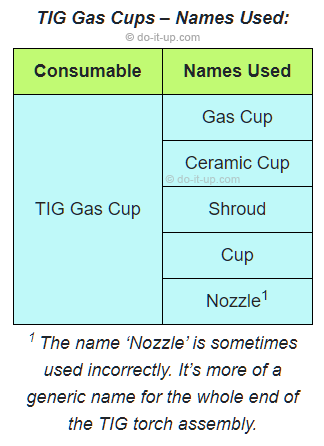

TIG Gas Cups – Names Used:

| Consumable | Names Used |

|---|---|

| TIG Gas Cup | Gas Cup |

| Ceramic Cup | |

| Shroud | |

| Cup | |

| Nozzle1 |

1 The name ‘Nozzle’ is sometimes used incorrectly. It’s more of a generic name for the whole end of the TIG torch assembly.

Gas cups come in a variety of sizes, dependant on the amount of shielding gas required around the Tungsten electrode. The amount of shielding gas needed, is often related to:

- The size of electrode being used.

- The material being welded.

- The amount of current being used.

The physical space to position the TIG torch (and the type of ceramic cup) can also be a factor.

Topics:

Types of TIG Gas Cups:

Gas Cups Types:

Ceramic Cups:

The majority of the ceramic cups you see are ‘Pink’ made from Zirconia and alumina. You can get gas cups made from other materials that have slightly different properties:

Most ceramic gas cups screws onto the gas nozzle and form a seal with the heat shield (insulator). There’s more information on How Gas Cups Fit below:

Types of Ceramic Cups:

- Ceramic Cups – Pink (Zirconia & Alumina):

- Ceramic Cups – Light Brown (lava ceramic):

- High Temperature Cups – Grey:

Ceramic Cups – Pink (Zirconia & Alumina):

The cheap and cheerful ‘pink’ gas cups are made for general, everyday use. If generating a large amount of heat (high amperage), then they can break after prolonged use.

Ceramic Cups – Light Brown (Lava & Alumina):

For higher temperature TIG welding. Generally available from more specialist suppliers.

High Temperature Cups – Grey:

For prolonged high temperature work, crack resistant (but more expensive). Generally available from more specialist suppliers.

Glass Cups:

The gas cup is made of heat resistant glass (Pyrex or quartz). They can cost more and are not as durable as the other types of gas cups. Therefore they tend to be used when visibility is important, i.e. Welding in awkward spots.

Often, the glass cups are just a piece of straight glass tube (tend to come in one size) and are held in place using o’rings. However, we are now starting to see different sized glass gas cups that have a thread so they can be screwed on (just like the standard ceramic type gas cups).

Flooding Cups:

As the name suggests, these cups are designed to ensure a good quality weld by improving the shielding gas coverage.

Stubby Cups:

Stubby cups are used in conjunction with a stubby gas nozzle. They reduce the size of the TIG gun so you can access tight spaces. If used in conjunction with a shorter back cap, and shorter tungsten electrode, the TIG torch can fit into even tighter spaces.

Furick Cups:

Furick is a brand name for a gas cup (and its diffuser, collet body (or gas nozzle), collet and heatshield). See Furick Fupa, Jazzy, BBW and Mooseknuckle). The cup (along with the gas nozzle) focus the shielding gas, allowing the tungsten electrode to protrude further out from the cup, giving better visibility and more access in tight spaces. They can be purchased as individual parts, or as a kit.

Notes:

- Matching the gas flow to the cup you’re using is important in achieving a good quality weld.

- Ceramic cups often have to match the gas nozzle type, the heat shield and the gun type.

- Make sure they fit your TIG torch before purchasing.

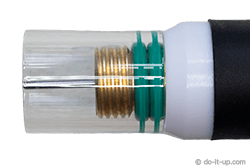

How to Fit Gas Cups:

Most gas cups screw onto the gas nozzle and fit flush against the heat insulator. Therefore the shape of the gas cup often has to be compatible with the shape of the heat insulator. The interface (fitment) between the gas cup and the insulator helps prevent shielding gas escaping in the wrong direction:

Buying Gas Cups:

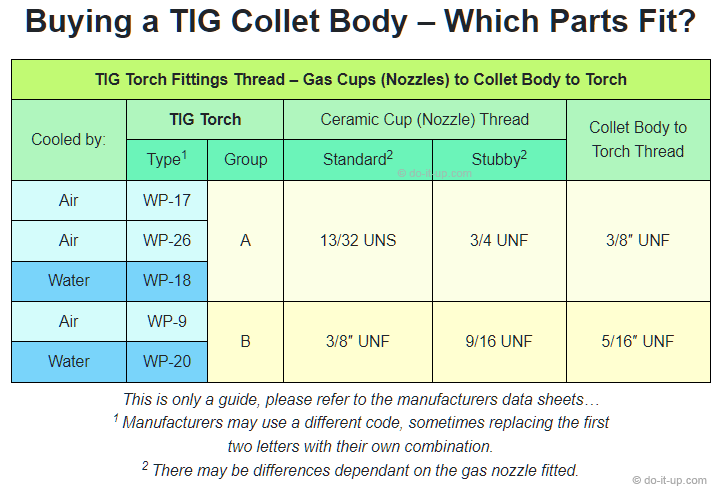

Buying Gas Cups – Which Parts Fit?

| TIG Torch Fittings Thread – Gas Cups (Nozzles) to Collet Body to Torch | |||||

|---|---|---|---|---|---|

| Cooled by: | TIG Torch | Ceramic Cup (Nozzle) Thread | Collet Body to Torch Thread |

||

| Type1 | Group | Standard2 | Stubby2 | ||

| Air | WP-17 | A | 13/32 UNS | 3/4 UNF | 3/8″ UNF |

| Air | WP-26 | ||||

| Water | WP-18 | ||||

| Air | WP-9 | B | 3/8″ UNF | 9/16 UNF | 5/16″ UNF |

| Water | WP-20 | ||||

This is only a guide, please refer to the manufacturers data sheets…

1 Manufacturers may use a different code, sometimes replacing the first two letters with their own combination.

2 There may be differences dependant on the gas nozzle fitted.

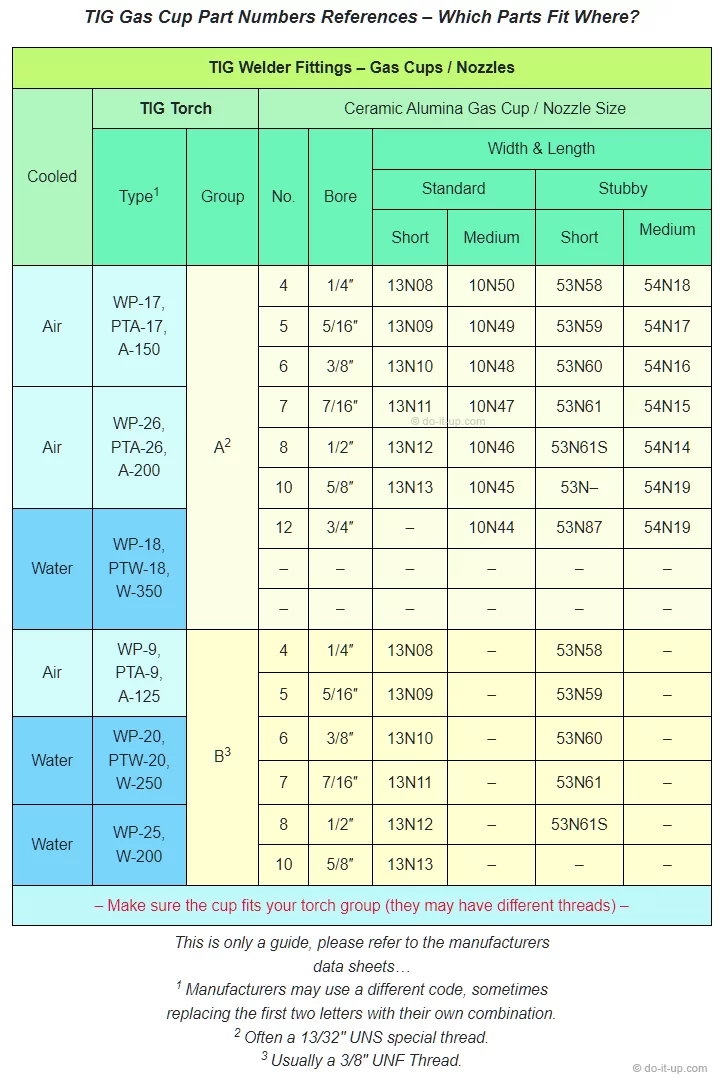

TIG Gas Cup Part Numbers References – Which Parts Fit Where?

| TIG Welder Fittings – Gas Cups / Nozzles | ||||||||

|---|---|---|---|---|---|---|---|---|

| Cooled | TIG Torch | Ceramic Alumina Gas Cup / Nozzle Size | ||||||

| Type1 | Group | No. | Bore | Width & Length | ||||

| Standard | Stubby | |||||||

| Short | Medium | Short | Medium |

|||||

| Air | WP-17, PTA-17, A-150 |

A2 | 4 | 1/4″ | 13N08 | 10N50 | 53N58 | 54N18 |

| 5 | 5/16″ | 13N09 | 10N49 | 53N59 | 54N17 | |||

| 6 | 3/8″ | 13N10 | 10N48 | 53N60 | 54N16 | |||

| Air | WP-26, PTA-26, A-200 |

7 | 7/16″ | 13N11 | 10N47 | 53N61 | 54N15 | |

| 8 | 1/2″ | 13N12 | 10N46 | 53N61S | 54N14 | |||

| 10 | 5/8″ | 13N13 | 10N45 | 53N– | 54N19 | |||

| Water | WP-18, PTW-18, W-350 |

12 | 3/4″ | – | 10N44 | 53N87 | 54N19 | |

| – | – | – | – | – | – | |||

| – | – | – | – | – | – | |||

| Air | WP-9, PTA-9, A-125 |

B3 | 4 | 1/4″ | 13N08 | – | 53N58 | – |

| 5 | 5/16″ | 13N09 | – | 53N59 | – | |||

| Water | WP-20, PTW-20, W-250 |

6 | 3/8″ | 13N10 | – | 53N60 | – | |

| 7 | 7/16″ | 13N11 | – | 53N61 | – | |||

| Water | WP-25, W-200 |

8 | 1/2″ | 13N12 | – | 53N61S | – | |

| 10 | 5/8″ | 13N13 | – | – | – | |||

| – Make sure the cup fits your torch group (they may have different threads) – | ||||||||

This is only a guide, please refer to the manufacturers data sheets…

1 Manufacturers may use a different code, sometimes replacing the first two letters with their own combination.

2 Often a 13/32″ UNS special thread.

3 Usually a 3/8″ UNF Thread.

Image Gallery:

– click or tap the image to view full size –