TIG Back Caps:

A TIG back cap is an insulator and:

- Provides protection against shorting out the Tungsten electrode that sticks out the back of the TIG torch.

- Provides a gas tight seal to prevent the shielding gas from leaking out the back of the TIG torch head.

- It applies pressure on the collet which holds the Tungsten electrode in place.

Topics:

TIG Back Cap Sizes:

Back caps typically come in 3 sizes (related to their length):

- Long (default size).

- Medium.

- Small.

A new Tungsten electrode is normally about 7″ (175mm) long. As the Tungsten electrode gets shorter, you can change the back cap to a smaller size. A smaller back cap allows the TIG torch to be used where space is restricted. So, keep some shorter Tungsten electrodes back for this purpose, rather than using the electrode up completely.

Notes:

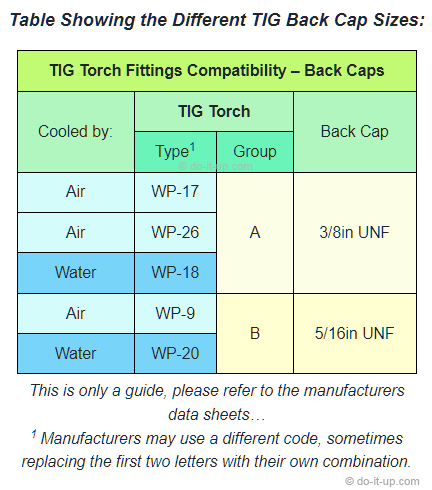

- Make sure the back cap fits your particular type and size of TIG torch before purchasing. See the table below for reference:

Table Showing the Different TIG Back Cap Sizes:

| TIG Torch Fittings Compatibility – Back Caps | |||

|---|---|---|---|

| Cooled by: | TIG Torch | Back Cap | |

| Type1 | Group | ||

| Air | WP-17 | A | 3/8in UNF |

| Air | WP-26 | ||

| Water | WP-18 | ||

| Air | WP-9 | B | 5/16in UNF |

| Water | WP-20 | ||

This is only a guide, please refer to the manufacturers data sheets…

1 Manufacturers may use a different code, sometimes replacing the first two letters with their own combination.

TIG Back Cap O’Rings:

Back cap o-rings prevent the escape of shielding gas from the back of the TIG gun head. More detail on back cap o’rings (such as size and type) can be found in the article ‘TIG O’Rings‘.

Notes:

- Occasionally, there is some discussion about lubricating the o’rings with silicone grease to help prevent damage to the o’rings and extend their life, (silicone grease doesn’t damage the o-ring material).

- If you decide to use some silicone grease on the back cap o’rings, you need to take care, as the silicone grease could cause weld contamination, especially as the TIG torch heats up and the silicone becomes more fluid.

Image Gallery:

– click or tap the image to view full size –