How to Measure & Buy a Replacement Bearing

Many ball bearings come in standard sizes. If the item you require is just an ordinary ‘standard type’, you can measure the size, (Bore x Outside Diameter x Width), or find the size in a parts manual. With this information, you can easily buy an ‘off the shelf’ ball bearing to replace one that’s worn out.

How to Select a Bearing?

– What Measurements or Information do I Need to Buy a Bearing –

– Choosing the Right One? –

As long as it’s not some weird and wonderful, specialised type, the information below is all you need to select and buy a bearing:

Note:

Make sure you measure the bearing in the correct format. Is it a metric or an imperial (inches) bearing? You can measure in either format, but in some cases, there may be a slight difference in size (dependant on the tolerances you’re working to?).

Information Required:

Additional Info:

Measuring The Size of Bearing:

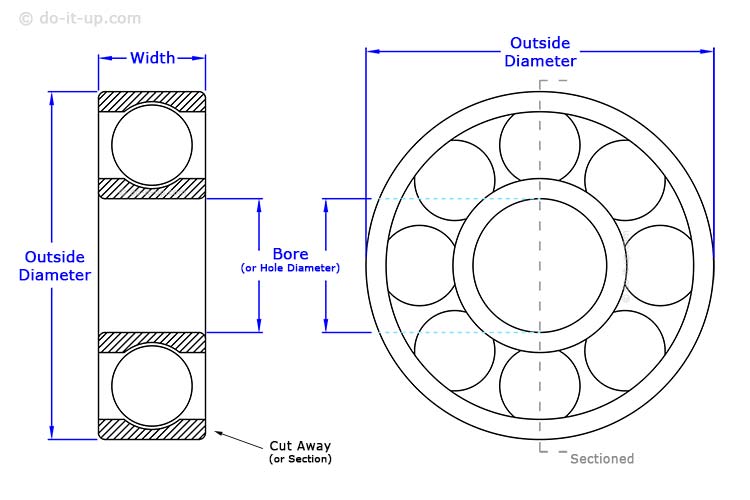

Use the following measurements, to find the size:

Bore (or hole diameter) x Outside Diameter x Width

or… Bore Ø x OD x W

The Type of Bearing:

There are generally four types…

Types of Bearing Available:

- Ball.

- Roller.

- Thrust Ball.

- Thrust Roller.

The basic requirement is to replace the bearing with the same type. Going by the names, you can generally select the correct type:

- A ball is in the shape of a ball,

- A roller is the shape of a garden roller, or a baked bean tin on its side.

- And a thrust bearing is where the load on the bearing is from the side.

The Type of Bearing Seal:

Bearings will often contain a seal to prevent the loss of lubricant and to prevent the ingress of dirt and debris. There are generally, two types of seal:

An Open Bearing:

This is where the bearing is open to the elements. It is therefore usually installed in a sealed protected environment or housing.

A Rubber Sealed Bearing:

This is where the open raceways are covered by a rubber seal to prevent the ingress of dirt and moisture.

These will have the abbreviation of: RS or 2RS

Note:

The rubber seal is generally thought to provide a better seal against ingress of dirt and moisture (compared to a steel seal).

A Steel Sealed Bearing:

This is where the open raceways are covered by a steel crimped seal to prevent the ingress of dirt and moisture.

These will have the abbreviation of: ZZ or 2ZZ

The Bearing Material:

Chromium Steel:

Chromium Steel has increased wear and corrosion resistance over plain steel.

Stainless Steel:

Stainless steel has increased wear and corrosion resistance over chromium steel (and are approximately twice the cost).

Ceramic:

Ceramics are used in the manufacture of the ball bearings. They are much harder than steel and provide high wear resistance (and are approximately four times the cost).

The Clearance:

The clearance (‘C’ rating) is the amount of play in the bearing. This sometimes needed due to heat expansion.

For precision (critical alignment) or where no great heat is generated, a ‘C’ rating is not required. E.g. a bicycle does not require a ‘C’ rated bearing.

The larger the number, the bigger the clearance: C3, C4, C5.

What’s Lubricant is the Bearing Filled With:

This isn’t always stated, (and you may have a personal preference?). But it’s always worth trying to determine whether oil or grease was used as the original lubrication in the bearing when new.

- Oil.

- Grease.

- Nothing?

Why Should I buy a Bearing Direct from a Supplier?

There are various types, and they come in a multitude of shapes and sizes. When you buy a bearing, sometimes it’s easier just to specify “I want a bearing for a widget machine” and the jobs done. But is it actually the easiest route to buying a bearing?

Positives (buying from the widget machine supplier):

- If it’s for a high-end product, where safety is involved, or there is a high cost for machinery downtime. It is best to get the OEM (or widget machinery suppliers) bearing for peace of mind.

- You don’t have to measure the actual size (Bore x Outside Diameter x Width), or find the size in a manual.

Negatives (buying from the widget machine supplier):

- Additional cost – If you buy from the original equipment supplier, there are added markup costs (in many cases, they will also buy in their bearing stock from an external supplier).

- The OEM supplier may be nowhere near you, if you need a bearing in a hurry.

“Buying direct, cutting out the middle man will always be because of cost or the speed of supply”. I would guess that 99.9% of manufacturer’s that use bearings, buy-in their stock.

Therefore, why not go directly to a bearing wholesaler (see the positives and negatives above), rather than to an original equipment supplier (who buys in their bearings)?